Get a quote, configure a custom safety solution or ask a question. We're here to help!

- Spill ContainmentMore …Loading Safety CagesMore …

SafeRack Worldwide

We pride ourselves on one-on-one customer service. When you call SafeRack, we'll be there to answer your questions with a combined experience of 400+ years.

Select your region below.- View Products

- Railcar & Truck Loading Platforms

- Gangways & Loading Ramps

- Stairs, Platforms & Ladders

- Mobile Ladders & Platforms

- Loading Arms & Fluid Transfer

- Safety Gates & Traffic Control

- Aviation & Aerospace Access

- Marine Access & Loading

- Grounding & Monitoring

- Spill Containment

- Loading Safety Cages

- Transloaders & Skids

- Shelters & Canopies

- Fall Protection

- Terminal & Speciality

Home / Industries / Bulk Chemical Loading / Hydrofluoric AcidHydrofluoric Acid Handling Design, Loading, and Installation.

Although no two Hydrofluoric Acid Loading solutions will be identical, the product itself determines much of the critical design criteria that will ensure that optimum safety and productivity can work together in harmony.

What is Hydrofluoric Acid? Hydrofluoric acid (HF) also referred to as Fluohydric or Fluoric acid is a clear, colorless corrosive liquid that is extremely hazardous. It’s typically shipped as a fuming liquid (48 to 52%) confined under its own vapor pressure.

The primary difference between hydrofluoric and hydrochloric acid is its solubility in water. HCI is a strong acid while hydrofluoric or HF is a weak acid. It’s called a weak acid because it doesn’t fully detach or separate into its ions in water, but it’s still a very dangerous acid.

In the United States, Hydrofluoric acid is typically a “tight-fill” (closed-loop) loading operation and is loaded into rail cars via chemical hoses or 3” stainless steel loading arms. Hydrofluoric acid, if not handled properly can cause serious injuries and Personal Protective Equipment (PPE) is required. Additionally, because operators are on top of the vehicles during the loading process, robust, well-designed fall prevention is essential to ensure increased throughput, without compromising operator safety.

Question, Get a Quote, Live Demo or Request an On-Site Visit

Our experts simplify the complex

View Full TextHydrofluoric acid is typically shipped in 10,000 gallon DOT-103 insulated or non-insulated tank cars with safety valves. The rails cars themselves are ~ 9′ outside diameter with an overall length of ~45’ to 50′, with a 6’ x 6’ center opening or off-set crash box openings.

Tank truck (un)loading procedures are similar to railcar applications with the trailers meeting established DOT requirements for transporting hydrofluoric acid or other like commodities. Approved DOT trailers include MC 307 or low pressure chemical ISO containers. Trailers and ISO’s are typically bottom unloaded. An extension pipe with two valves is flanged to the top of the trailer. All trailers must be equipped with pressure relief valves, and trailers with bottom outlets must be equipped with remote controlled stop valves.

Your Project

Typically, as a starting point, we will need to know answers to these questions for your project

- The Railcar connection locations need flexibility – Do you know what the breadbasket connections look like?

- Are you using liquid and vapor arms/hose as two separate devices or a piggyback arm?

- Is the loading station indoors or outdoors?

- Is the loading area temperature controlled?

- How are you going to spot your railcars

Our highly trained technical sales team will undertake a detailed site survey prior to undertaking any work to check and clarify all dimensions, obstructions, access issues and other salient points. Our challenge is to provide the safest working environment – protecting operators and the equipment – while simultaneously enabling you to improve throughput and productivity.

Your Project Needs

Whether you are looking for a turn-key installation, on-site supervision or a maintenance program, SafeRack is positioned to assist you. We can do as little or as much as you need. Our project management and supervision team is the best in the business at supporting your company’s needs.

- Collaborative Design – Our loading platform specialists will work with you one on one, if you design to design the best loading solution for your specific needs

- Contract review – drawings and associated documents relating to the contract prior to site arrival

- Risk Assessment – Undertaking a site risk assessment

- Shipment Inspection – Detection of any shipping damage or abnormalities

- Material Receiving – Supervised off-loading and transport at site

- Installation Management – Supervised Installations and Coordination

- Start-up & Commissioning – On-site training for both users and maintenance personnel

Loading Arms

Generally speaking, SafeRack recommends rigid pipe loading arms where possible for the following reasons:

- Balanced throughout their movement envelope

- Designed not to hit the ground – protecting the asset and the operator

- Ergonomic – one man operation

- Fitted with manual or actuated valves.

- Fitted with optional purge/vent facilities

- Can be moved into position with ease and left hanging in the air while the operator prepares the tanker connection

- Parked neatly

Hoses require:

- Annual pressure test

- Are difficult to stow neatly when not in use

- Can be dropped

- Can be driven over

- Are very heavy to use if fitted with a valve at the tanker connection point

- Cannot be easily heated or have vent/purge valves fitted to it

- Prone to catastrophic failure

Typical Hydrofluoric Acid Loading Platform

Quote or discuss your installation.

Start by selecting loading application"*" indicates required fields

Below are some of the loading and unloading solutions for illustrative purposes only. Our experts will work with you and your team for a custom solution to suit your needs.

Hydrofluoric Acid Loading

Chloroform is typically loaded into railcars or tank trucks via boom supported carbon or stainless steel loading arms or chemical hoses with a flange connection. The arm or hose will have a top inlet with a control valve to ensure that it is self-draining after use and is supported along the length of a mechanical loading arm to improve handling; this is known as a by-pass arm. You can install one liquid and one vapor arm, or mount both the liquid and vapor hoses on one by-pass arm. For unloading, typically you would use a carbon steel self-draining loading arm or chemical hose with Kalrez, PTFE or Viton seals. Purge lines can be fitted to the arm, for nitrogen purging. Additional features such as parking latches with proximity sensors can be incorporated into the total system to ensure the arm is correctly stowed when not in use, before any rail movement can occur.

Loading Gangways and Safety Cages

A wider access gangway (48″-60″ is preferable) as it helps improve access and egress to and from the vessel. In addition, a wider gangway will reduce the risk of the operator’s PPE getting caught, torn or damaged, and will improve productivity and safety. Powered gangway solutions are also an option, with both hydraulic and pneumatic solutions being commonly used. Each gangway will be fitted with a two-rail safety cage for the railcar crash box. This will be a centered 6’x6’ safety cage to sit directly over the cashbox. This will provide a safe, secure work environment for your operator when connected to their breathing apparatus.

SafeRack’s GX SAS gangways use Retractalok power-assist technology allowing operators to raise or lower effortlessly, light as a feather to lift, and solid as a rock. Tested in the most critical applications, this revolutionary new gangway outperforms all others. Available in multiple lengths and widths.

Learn MoreMAXRack Elevating Safety Cage

As an alternative to our two and four-rail safety cages, some customers prefer our MAXRack elevating safety cages. The ultimate fall prevention solution engineered to keep operators safe and productive. Designed for both trucks or railcars, and available in multiple cage lengths and widths. Safe, durable, and easy to use. MAXRack is built rock-solid with galvanized steel column supports and lifting arms (cages can be Aluminum, Galvanized, or Stainless Steel depending on application) Available in two power options – Pneumatic Air Drive and Electric Drive (Explosion and Non-Explosion Proof).

As an alternative to our two and four-rail safety cages, some customers prefer our MAXRack elevating safety cages. The ultimate fall prevention solution engineered to keep operators safe and productive. Designed for both trucks or railcars, and available in multiple cage lengths and widths. Safe, durable, and easy to use. MAXRack is built rock-solid with galvanized steel column supports and lifting arms (cages can be Aluminum, Galvanized, or Stainless Steel depending on application) Available in two power options – Pneumatic Air Drive and Electric Drive (Explosion and Non-Explosion Proof).

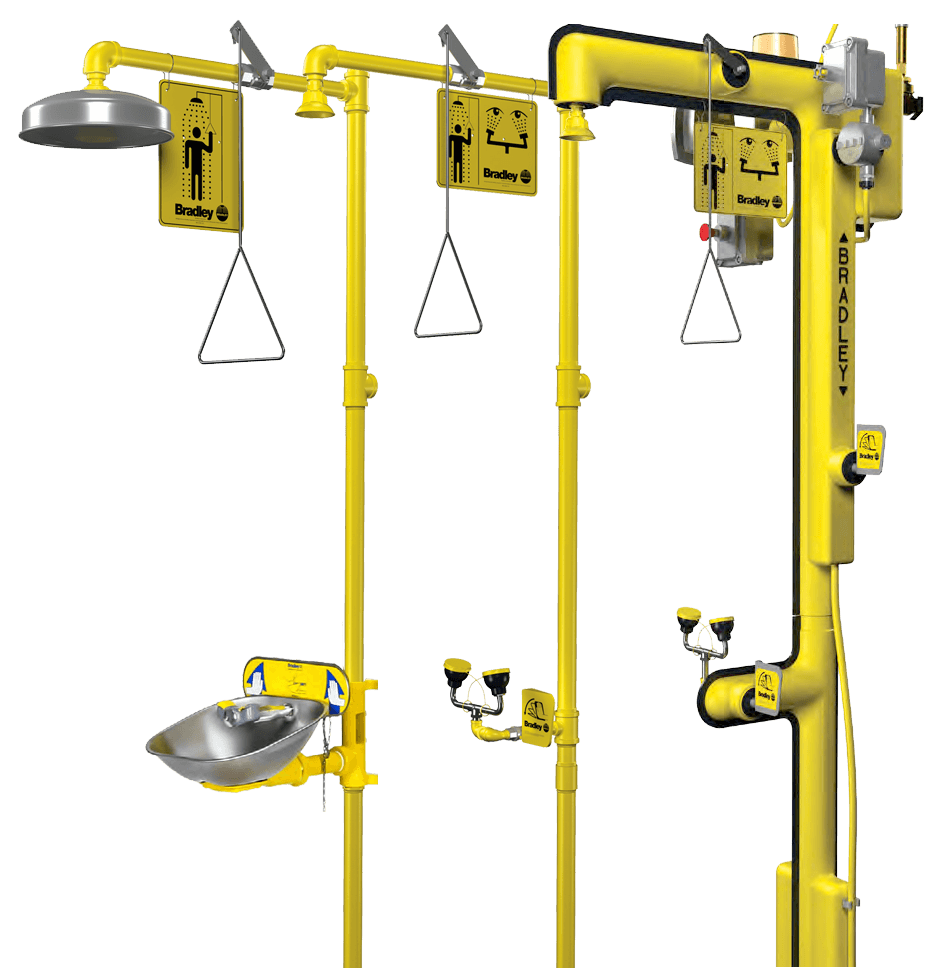

Learn MoreHydrofluoric Acid Eye Wash/Drench Showers

ANSI guidelines state that an Eye Wash/Drench Showers need to be located 10 seconds or 55’ (16.8m) from contaminants or hazardous materials. Eyewash stations need to be on the same horizontal plane with no obstructions.

Therefore, we would propose the installation of a standard combination Drench Shower/Eyewash Unit, which will save limited space and fit easily into any work environment.

Hydrofluoric Acid Spill Containment

Spill containment pans will be provided at the point of loading operations and is an essential piece of equipment in overall site safety and environmental protection. Hydrofluoric Acid Grounding

Vinyl acetate is a non-combustible liquid and vapor. Industry best practice includes the grounding of all vessels before starting the (un)loading process. - Ground controllers — ensure true grounding before product flow is permitted

- Non-sparking tools are also recommended while working around this product

Hydrofluoric Acid Safety Gates

Safety Gates will be installed at the top of stairs and any other openings to ensure operator safety at all times.  YellowGate Safety Gates

YellowGate Safety GatesSafeRack’s line of industrial safety gates is the most flexible product on the market with the ability span openings between 16″ and 36″ and is field adjustable with nothing more than a wrench. Learn More

Hydrofluoric Acid Options

- Lighting – Lighting both over and under the platform will be provided. For overcast days or second shift, lighting is essential for improved safety and improved productivity.

- Platform & Canopies – Full platform canopies reduce exposure to the elements and improve the safe and productive loading operation from the operator’s perspective.

- Operator Shelter – Depending on your site requirements, consideration should be given to the requirement of an operator or guard building on the loading platform. This can be customized to meet specific site requirements.

- Wheel Chocks – Railcar Wheel Chocks provide fast blocking of all types of railcars and meet OSHA regulations to safely prevent railroad cars from moving during loading or unloading operations. This is a requirement by the Department of Homeland Security.

Personal Protective Equipment PPE Requirements

Eye/Face Protection: Wear chemical safety goggles. A face shield (with safety goggles) may also be necessary.

Skin Protection: Wear chemical protective clothing e.g. gloves, aprons, boots. Coveralls or long sleeve shirts and pants in some operations. Wear a chemical protective, full-body encapsulating suit, and self-contained breathing apparatus (SCBA). Suitable materials include: butyl rubber, neoprene rubber, Viton®, Viton®/butyl rubber, Barrier® – PE/PA/PE, Silver Shield® – PE/EVAL/PE, Trellchem® HPS, Trellchem® VPS, Saranex®™, Tychem® BR/LV, Tychem® Responder® CSM, Tychem® TK. The following materials should NOT be used: natural rubber, polyvinyl chloride. Recommendations are NOT valid for very thin neoprene rubber gloves (0.3 mm or less).

Respiratory Protection: Up to 5 ppm:

(APF = 10) Any chemical cartridge respirator with cartridge(s) providing protection against chlorine*; or Any supplied-air respirator*.

*Reported to cause eye irritation or damage; may require eye protection.

APF = Assigned Protection Factor

Recommendations apply only to National Institute for Occupational Safety and Health (NIOSH) approved respirators. Refer to the NIOSH pocket guide to chemical hazards for more information.

Use a local exhaust ventilation and enclosure, if necessary, to control the amount in the air. Consider using a corrosion-resistant exhaust ventilation system separate from other ventilation systems. It may be necessary to use stringent control measures such as process enclosure to prevent product release into the workplace. Use backup controls (e.g. double mechanical pump seals) to prevent the release of this material due to equipment failure. * For illustrative purposes only. Our experts will work with you and your team for a custom solution to suit your needs Customer Reviews

5 5Our sales rep Mark Gardner, was at the top of his game.

5 5Our sales rep Mark Gardner, was at the top of his game.Product was delivered fast and on time. Our sales rep Mark Gardner, was at the top of his game on responses to our questions. The product is well built and will keep our workers safe on the tracks.

By Dale Porter from E.I. DuPont de Nemours and Company on 10/17/14 5 5Extremely Satisfied

5 5Extremely SatisfiedVery well built, easy assembly, exactly what we needed, and great assistance in determining our needs.

By Macio Shankle from Dradura on 4/20/22 4 5As usual, just what I wanted and expected.

4 5As usual, just what I wanted and expected.Mark Gardner took my order and did everything he could to complete my request and get my items to the job site on time… As usual, just what I wanted and expected… I have used these products at multiple locations and they have always performed flawlessly.

By Jason Boaz from Darling Ingredients Inc. on 10/12/154 5I always talk to a real person, no automated phone systems.Linda Hardee got back to us within half an hour of our request. She is pleasant to work with, and I always talk to a real person, not like the automated phone systems.

By Chris Sholten from Associated Northwest on 11/7/11 5 5Submitted our order with minimal knowledge of the original installation.

5 5Submitted our order with minimal knowledge of the original installation.Stephen did a good job of getting up to speed quickly and submitting our order with minimal knowledge of the original installation. I imagine this was company-wide effort as well. Thanks for the help.

By Stephen Roach from Progressive Builders Inc on 9/12/12 4 5World class product with sophisticated technology.

4 5World class product with sophisticated technology.World class product with sophisticated technology; user friendly and safe; excellent engineering. The company brand itself is so popular, with the addition of your company name – SafeRack, which means “second name for safety.” Easy to assemble and maintain. Very economical and great value for your money. Vey compact and safe. We will recommend to all because of its unique features and reliability.

By Ashish Moghe from Dover India Pvt. Ltd. on 4/30/13MAJOR HYDROFLUORIC ACID PRODUCERS WHERE WE HAVE SUCCESSFULLY EXECUTED HYDROFLUORIC ACID LOADING PROJECTS

Hydrofluoric Acid 101

Things to know about Hydrofluoric Acid

Hydrofluoric acid is regulated by the U.S. Department of Transportation (DOT) and is classified as a corrosive material with the DOT identification number UN 1790.

Aqueous hydrofluoric acid is a solution of hydrogen fluoride in water. It’s used as a catalyst and/or raw material in the manufacturing of refrigerants, herbicides, high-octane gasoline, pharmaceuticals, electrical components and fluorescent light bulbs.

HF reacts with many materials; therefore best practice includes avoiding contact with glass, concrete, metals, water, other acids, oxidizers, alkalis, organics and ceramics. Suitable storage includes polyethylene, fluorocarbon plastic, or lead containers.

Only properly trained and equipped personnel should be permitted to (un)load hydrofluoric acid tank cars and tank trucks. Operators should wear approved PPE equipment including impervious clothing, footwear, gloves, and goggles. Exposure to more than 25% of the body can be fatal, as the fluoride ions will migrate through the human body destroying tissue until it finally lodges in the bones.

HF is dangerous to human health, acute exposure can cause respiratory irritation and organ toxicity. Exposure to more than 25% of the body can be fatal, as the fluoride ions migrate through the body rapidly destroying tissue until it finally lodges in the bones.

Do not breathe dust/fumes/mist/vapors. Use only outdoors, or in a well ventilated area. Thermal decomposition can lead to a release of irritating gases and vapors.

First aid measures for exposure include – removing operators from the source of exposure and into fresh air. Remove contaminated clothing immediately; wash skin thoroughly with soap and water; flush eyes with tepid water for 15 minutes. If ingested do not induce vomiting, but immediately call your local poison control center. Aspiration into the lungs can cause fatal chemical pneumonitis. If ingestion has occurred, assume there is a risk of aspiration into the lungs.

Hydrofluoric acid is an extremely aggressive chemical and attacks most metals including aluminum, carbon and stainless steel. SafeRack recommends galvanized steel and/or powder coated products for corrosion resistance.

Is your plant or facility compliant with ANSI, OSHA, and local safety codes? We can help!

EMERGENCY EYEWASHES / SHOWER EQUIPMENT AND THE ANSI/ISEA Z358.1 – 2014 STANDARD

Following eye contact, you must start washing with water immediately to prevent permanent damage. In the event of skin contact, you must start washing with water immediately to prevent slow-healing chemical burns.

Are you aware that ANSI guidelines state that Eye Wash/Drench Showers need to be located 10 seconds or 55′ from contaminates or hazardous materials and located on the same horizontal plane, with no obstructions? If bottom loading/unloading, an additional shower should be located at grade as well. SafeRack provides the above equipment plus much more needed to keep employees safe and expedite bulk chemical loading and unloading.

OSHA Regulation Experts – Does your existing chemical safety equipment or chemical loading systems meet OSHA’s latest requirements? SafeRack’s professional technical sales consultants are available to meet with your team to make recommendations to keep your facility in front of OSHA’s ever-changing country and region-specific standards and regulations, including lifeline and trolley beam fall arrest systems, metal stairs, and access platforms.

Why SafeRack?

The SafeRack approach is a collaborative one. Let’s call it The SafeRack Way. We have, over many years amassed a great deal of experience and understanding of the safety aspects involved in loading road tankers and railcars, as well as the behavioral habits of the operators.

Experts In Chemical Loading

- Acetic Acid

- Acetic Anhydride

- Acetonitrile

- Acrolein

- Acrylic Acid

- Acrylonitrile

- Aluminum Chloride

- Aluminum Sulfate

- Ammonia

- Ammonium Hydroxide

- Ammonium Nitrate

- Aniline

- Benzene

- Benzyl Chloride

- Bromotrifluoromethane

- Butadiene

- Carbon Dioxide

- Caustic

- Chlorine

- Chloroform

- Chlorosulfonic Acid

- DEF (Diesel Exhaust Fluid)

- Diethylene Glycol

- Dimethylformamide

- Dodecylbenzene Sulfonic Acid

- Ethanol

- Ethyl Acetate

- Ethyl Chloride

- Ethylene

- Ethylene Dichloride

- Ethylene Glycol

- Ethylene Oxide

- Ferric Chloride

- Ferrous Chloride

- Hexane

- Hydrochloric Acid

- Hydrofluoric Acid

- Hydrofluorosilicic Acid

- Hydrogen Cyanide

- Hydrogen Peroxide

- Hydrofluoric Acid

- Hypochlorous Acid

- Isopropyl Acetate

- Liquid Argon

- Liquid Nitrogen

- Liquid Oxygen

- Maleic Anhydride

- MDI

- Methanol

- Methyl Chloride

- Methyl Ethyl Ketone

- Methyl Methacrylate

- Methyl Isocyanate

- Molten Sulphur

- Nitric Acid

- Oleum

- Phenol

- Phosphoric Acid

- Phosphorus Oxychloride

- Phosphorus Trichloride

- Polypropylene

- Renewable Diesel

- Sodium Cyanide

- Sodium Hydroxide

- Sodium Hypochlorite

- Styrene Monomer

- Sulfuric Acid

- Sulfur Dioxide

- Titanium Tetrachloride

- Toluene

- Toluene Diisocyanate

- Turpenitne

- UAN (Urea Ammonium Nitrate)

- UREA

- Vinyl Acetate

- Vinyl Chloride

- Xylene

- Zinc Chloride

- Agro-Chemical

- Specialty Chemical

- Petrochemical

North America’s largest loading terminal

World-leading designer, manufacturer, and installer of truck and railcar loading platforms

As one of the primary railcar loading points, Hardisty is one of the major crude oil hubs in North America and a major origination point of pipelines that export to the United States. SCS was asked to supply and construct a SafeRack crude oil loadout terminal spanning nearly half a mile. The USD Hardisty terminal can load up to two 120-railcar unit trains per day and consists of a fixed loading rack with 62 railcar loading positions enclosed, separate control, operator, and mechanical buildings, as well as a unit train staging area and loop tracks capable of holding multiple unit trains simultaneously. SCS also supplied and installed boom-supported loading arms with supply and vapor management systems.

Quick Quote 866-761-7225

LET US DESIGN YOUR SOLUTION TODAY

Our innovative tools provide 3D visualizations and accurate quotes in minutes.

Get Help NowOrder Now 866-761-7225

Questions or Need a Quote?

Chat live with a knowledgeable and friendly safety expert now.

Bob Kashtan

Located in South Carolina

Joey Robinson

Located in South Carolina

Caelin Lacy

Located in South Carolina

Katie Kelly

Located in South Carolina

Amber Graham

Located in South Carolina

As an alternative to our two and four-rail safety cages, some customers prefer our MAXRack elevating safety cages. The ultimate fall prevention solution engineered to keep operators safe and productive. Designed for both trucks or railcars, and available in multiple cage lengths and widths. Safe, durable, and easy to use. MAXRack is built rock-solid with galvanized steel column supports and lifting arms (cages can be Aluminum, Galvanized, or Stainless Steel depending on application) Available in two power options – Pneumatic Air Drive and Electric Drive (Explosion and Non-Explosion Proof).

As an alternative to our two and four-rail safety cages, some customers prefer our MAXRack elevating safety cages. The ultimate fall prevention solution engineered to keep operators safe and productive. Designed for both trucks or railcars, and available in multiple cage lengths and widths. Safe, durable, and easy to use. MAXRack is built rock-solid with galvanized steel column supports and lifting arms (cages can be Aluminum, Galvanized, or Stainless Steel depending on application) Available in two power options – Pneumatic Air Drive and Electric Drive (Explosion and Non-Explosion Proof).

YellowGate Safety Gates

YellowGate Safety Gates