Fall clearance (or freefall distance) is the distance required to stop a falling worker from an elevation safely as a crucial part of an effort in industrial fall protection. When completing a risk assessment for work that has the potential to expose workers to free fall arrest, safety managers must determine fall clearance. Impediments or structures that may be impacted in the case of a fall must be considered.

The anchor’s position, the fall arrest lanyard’s length, break the distance, and the free fall distance is all factors to consider.

The fall clearance between an elevated worker and the nearest impact or obstruction must be greater than or equal to two times the potential free fall distance. Thus, if a worker falls two stories high, their fall arrest equipment must have enough strength. OSHA recommends:

- A distance of no more than 6 feet (1.8 meters), depending on the lanyard length and connection point location.

- When worn with a body belt, the maximum arresting force is 900 pounds (4 kN). With a body harness, the leading arresting force should be 1,800 pounds (8kN).

- Choose components, materials, anchors, and connectors suitable for the application, hazards, and work environment. This is known as a competent person and requires official qualifications.

How to Calculate Fall Clearance

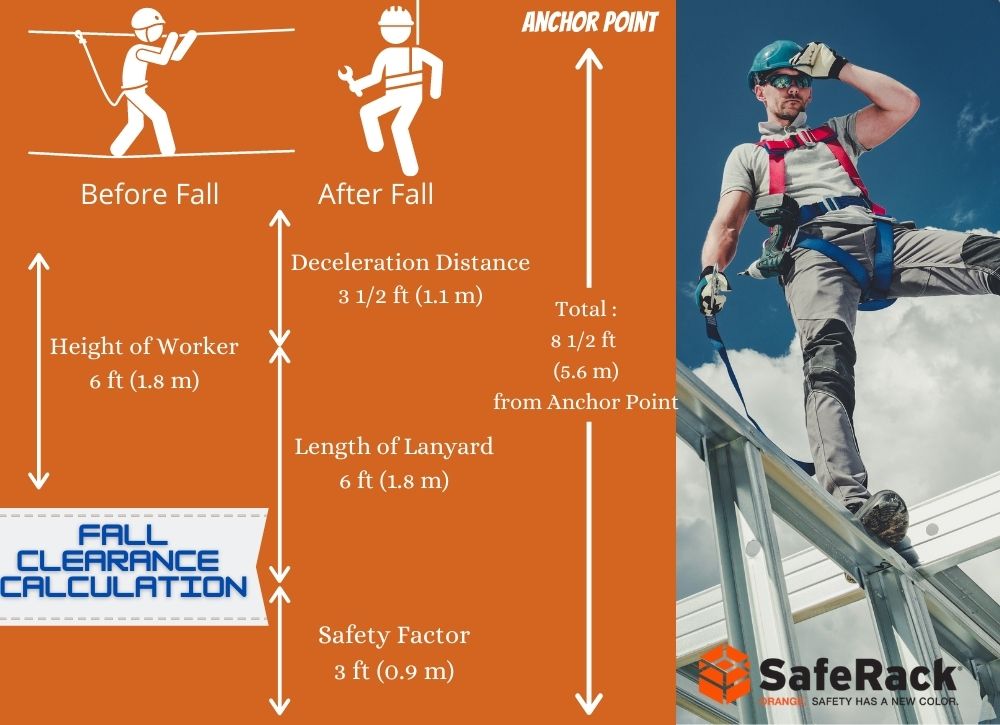

Required Distance = Lanyard Length + Deceleration Distance + Height of the Worker + Safety Factor

Because fall prevention systems are intended to save lives, the equipment’s efficiency and longevity are critical. Before any system or equipment is utilized as the first line of defense against the risks of defective equipment, people in charge of facility and operations must perform a visual assessment of the system and equipment. It’s also crucial to figure out how often workers will use the system and what kind of environment they’ll operate in. As a precaution, corrosive, hostile conditions or heavy use will necessitate more regular inspections.

While it is necessary to have specially developed equipment to keep employees safe on leading and sharp edges, such equipment is only practical if workers comprehend how to use it and why it is necessary. Appropriate training is critical to ensuring workers are fully engaged and aware of the particular dangers associated with operating at height in various applications. Employers should offer their teams ongoing training that complies with OSHA and ANSI standards to guarantee worker safety on the job. Additionally, some fall protection suppliers provide on-site training to assist workers in better understand and avoid the hazards connected with working at height, particularly the risks associated with sharp and leading edges.

The bottom line is that you need to maintain the safety of your employees. Be aware of the dangers and hazards on your job site, supply the necessary fall protection equipment, and teach employees how to utilize this critical piece of equipment properly. These are the fundamental procedures essential to prevent death or injury in the case of a fall.