Liquid Terminal Experts

SafeRack specializes in simple to complex loading rack products and solutions for the liquid terminal industry

Question, Get a Quote, Live Demo or Request an On-Site Visit

Our experts simplify the complex

Coordinating loading arms with gangways, fall protection, OSHA compliance, and all the vehicle variables can be complex. SafeRack’s products and industry experts can help.

Safety is our top priority – All our products and solutions improve efficiencies while meeting or exceeding OSHA regulations

Seamless Coordination, Safer Solutions. In addition to years of experience outfitting liquid transfer systems, SafeRack brings new technology to the industry, which improves loading arm durability and maintainability. This new line of products pair heavy-duty construction with the simplicity of a three-piece design to provide long-lasting, hassle-free performance and the quickest and easiest disassembly and repair in the industry.

SafeRack Fly-In Program

Learn and benefit from SafeRack’s innovative products and solutions. We will fly you out to our facility to:

EDUCATE

Comprehensive, hands-on training with the industries latest technology.

ENGAGE

Collaborate with industry experts to understand what success looks like and create better outcomes.

EXPLORE

Explore the ways you can improve the overall performance of your facility.

SafeRack is the #1 selling Gangway in North America

Made in the USA, SafeRack’s railcar gangways, truck gangways, and marine gangways, are reliable, highly engineered & safe.

- Consultative Approach – We can visit your site to develop a solution that’s right for you

- Expedited Access Gangway Delivery – Quick order processing, in-stock and ready to ship replacement parts

- Highly Engineered Access Gangways – Advanced, innovative designs are proven in the field to be easy to use for faster throughput, safely.

- Quality-Access Gangway Manufacturing – Proudly made in the USA

- Precision Built Access Gangway- Our aluminum access gangways use fewer parts and fewer welds result in stronger, longer-lasting solutions that require less maintenance

- Specialized Applications – Specialty gangways and cages are ideal for the cement and frac sand industries

Loading Platforms

SafeRack is the world leading manufacturer and integrator for railcar and truck loading.

- Increased Railcar and Truck Loading Productivity –Safer, ergonomically designed systems boost productivity in your truck and railcar loading racks.

- Better Value – Every truck and railcar loading platform system comes with world-class customer service, advanced technology, quality designs and years of experience.

- Collaborative Approach – We coordinate with your team, local engineering and other key stakeholders to provide complete—and seamless—solutions for truck and railcar loading platforms and systems.

- Superior Service – We listen, we ask the right questions and we’re on-site (and available) throughout the entire process, from design and engineering to manufacturing and installation of your railcar and truck loading platform facility.

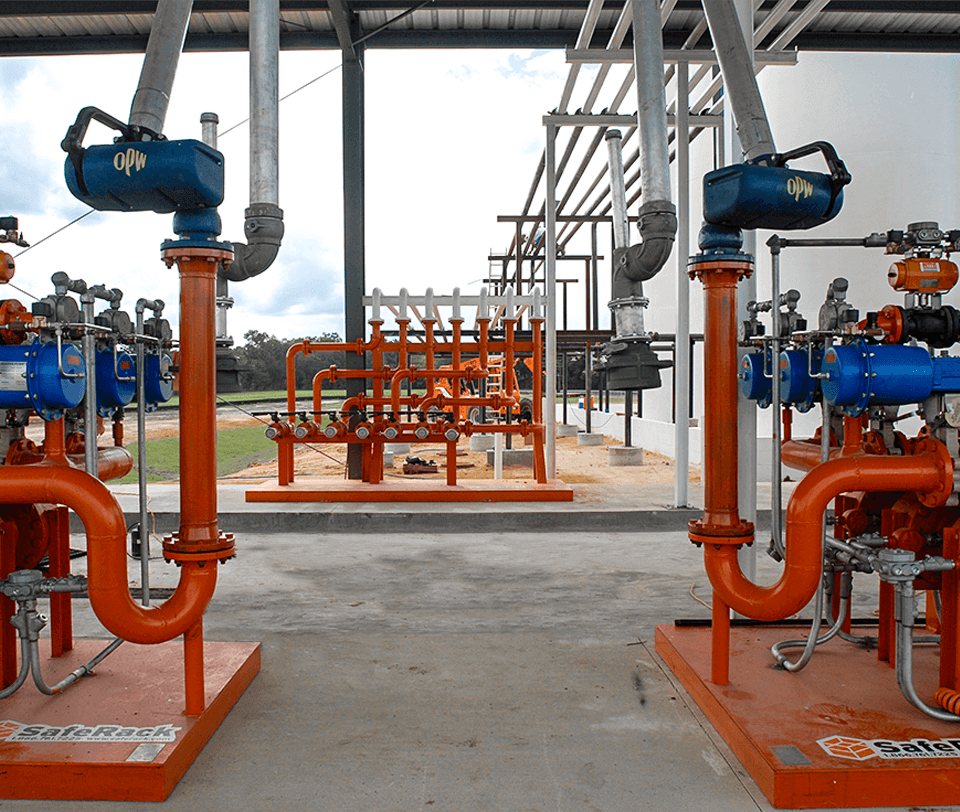

Loading Arm Systems and Components

SafeRack supplies more OPW and Emco Wheaton loading arm systems than anyone in North America.

SafeRack supplies more OPW and Emco Wheaton loading arm systems than anyone in North America.

- Overfill and Vapor Recovery – Truck and Railcar Liquid Level Sensors and Vapor Recovery Solutions

- Grounding and Metering Systems – Truck and Railcar Grounding and Metering Systems

- Design and Installation – Coordination Vehicle Variables, Gangway and Fall Protection

- Insulation and Heat Tracing – Insulated, Steam Jacketed and Heat Traced Options

- Couplings and Disconnects – Breakaway Couplings and Dry Break Disconnects

Grounding & Monitoring

Our out-of-the-box solution ensures your truck or train is properly grounded before loading begins, protecting your employees and property from accidents.

- Ground controllers — ensure ground before product flow

- Explosion-proof enclosures — meet or exceed UL, CSA and Ex requirements

- Overfill prevention — can be integrated for maximum safety

Metal Work Platforms & Stair Systems

Save time and money by eliminating custom fabrication with ErectaStep’s prefabricated work platforms, crossovers and stair systems.

Save time and money by eliminating custom fabrication with ErectaStep’s prefabricated work platforms, crossovers and stair systems.

- Why Go Custom – Our metal stair and work platforms costs Less Than Custom-Engineered Systems

- Quoted In Minutes – Metal stair and work platform quotes, and Drawings in minutes, not weeks.

- Reconfigures Easily – Our metal stair and work platforms unbolt, Reconfigure and Relocate in a snap

- Installs Fast! – Our metal stair and work platforms require no welding, special tools or cranes

- Always OSHA Compliant – Our metal stair and work platforms are built to OSHA compliance guidelines

Industrial Safety Gates that are Durable, Safe and Adjustable.

YellowGate’s universal mounting system protects every passageway in your facility with one SKU.

- Easy to install & OSHA compliant

- Adjustable from 16″ to 36″

- Mounts anywhere, no additional parts needed

- Field Adjustable – No cutting, welding or drilling required

- Opens to an angle of 108 degrees

Spill Containment Solutions

Protect yourself from industrial spills with the best prevention, containment, and cleanup solutions on the market. With SafeRack’s wide range of spill containment products and our knowledgeable sales staff, we have the solutions for your application or project.

- Prevention, Containment, and Cleaning Solutions

- Protect the Environment and Your Bottom Line

- Portable and Permanent Systems

- Hundreds of solutions, ranging from 100-yard railcar track pans to 1-foot utility trays

Skids and Transloaders – Petroleum and Chemical

SafeRack’s skids and transloaders are proudly made in our state-of-the-art manufacturing facility in Andrews, SC. It’s where you’ll find our full staff of engineers and designers ready to provide you with high-quality, turnkey solutions.

- Standard and Custom Solutions Available

- Built with Quality Materials in the USA

- Proven, Reliable Technology

Truck & Railcar Features

Truck side features grounding protection, overfill monitoring and metering for custody transfer. Railcar side allows options for unloading as well as safe access to hatch area of railcar.

Coordination is Key

SafeRack has Solutions for Complex Challenges

Coordinating loading arms with gangways, fall protection and all the vehicle variables in truck loading racks or railcar loading platforms is very complex. The experience, user familiarity, technology and dedication to safety and productivity are reasons why users from all over North America are coming to SafeRack.

In addition to years of experience outfitting liquid transfer systems, SafeRack brings new technology to the industry, which improves loading arm durability and maintainability. This new line of products pair heavy-duty construction with the simplicity of a three-piece design to provide long-lasting, hassle-free performance and the quickest and easiest disassembly and repair in the industry.