Gangways used in the marine environment date back almost as far as the existence of boats. Granted the gangways used in 1 B.C. were very basic and unsafe, but they need to load (embark) and unload (disembark) has always been there. The purpose of a gangway is to make access to and from a ship, barge, or boat easier and safer.

Gangway styles vary based on application, need, and location. The most popular styles include Self-adjusting Stairs, Stage and Truss, and Aluminum and Wooden Ramps / Stairs. They also adfix and operate in different ways such as folding, expanding, and permanently fixed.

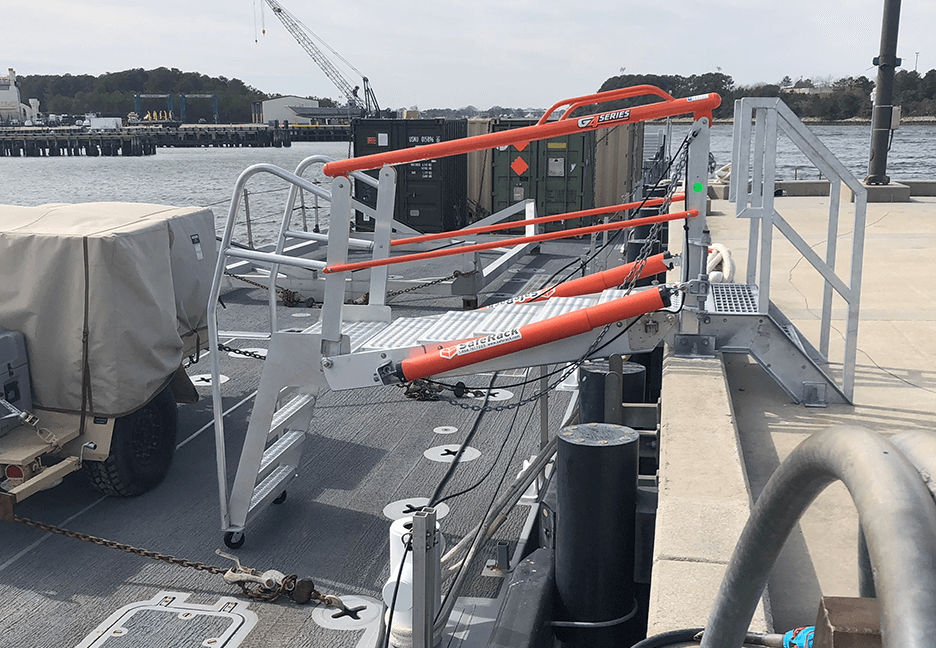

Self-Adjusting Stair Gangway (SAS) marine gangway is a perfect solution to reach both short and intermediate distances, providing a slip-resistant and level step for users along the entire length of the gangway.

Self-Adjusting Stair Gangway (SAS) marine gangway is a perfect solution to reach both short and intermediate distances, providing a slip-resistant and level step for users along the entire length of the gangway.

Stage and Truss Gangways provide a standard distributed load capacity of 60 pounds per square foot and can be custom constructed to accommodate even higher load capacities. Additionally, they can have four different cleat styles to improve footing when operating at steeper angles. They can also have extruded and open-grating decking, as well as decking, fabricated from aluminum sheet or tread plate.

Stage and Truss Gangways provide a standard distributed load capacity of 60 pounds per square foot and can be custom constructed to accommodate even higher load capacities. Additionally, they can have four different cleat styles to improve footing when operating at steeper angles. They can also have extruded and open-grating decking, as well as decking, fabricated from aluminum sheet or tread plate.

Flat Access Gangways are one of the most popular styles of gangways when it is safe to have a level plan, with an incline/decline or flat. They often feature a slip-resistant walk surface and, with the use of the telescoping extension, can eliminate gaps. They can be constructed of aluminum, steel, or even wood. Of course, wood is not an ideal material to have within a moisture-rich environment.

The type of access needed for the ship, barge, or boat will vary based on a few criteria. The criteria will help determine the type of gangway needed. Consider these questions:

- How high up (or down) will the access be to the vessel from the dock or terminal?

- How close to the water will the gangway be?

- Will the access points vary either on the same type of vessel or multiple vessels coming in?

- What variations in temperature will the environment incur, or will it be mostly inside?

- What types of items, or how many people will need to be using the gangways to load and unload the vessel(s)?

- Where will the gangway be affixed? Does it need to fold, retract or can it be extended at all times?

When it comes to specifying a gangway for a marine environment it is important to know the options as well as the criteria to choose the access that will be the most effective and safe. The best way to go about gangway purchasing is to consult experts that install and/or sell these types of products in the application. Note that not all suppliers are properly equipped to supply gangways for all environments. A marine environment has its own challenges, and requirements, and regulations.

SafeRack’s aluminum gangways for barge access and ship access are constructed of durable corrosion-resistant marine-grade aluminum and built to last. Gangways are available in sizes up to 50′ in length and 5′ in width. Our marine gangways are designed for OHSA-compliant worker safety, durability, and reliability in marine environments and are built-to-order to your required length and specifications. Learn about all of SafeRack’s marine products and solutions.