This SafeRack access platform and gangway at a Marathon Refinery gives workers access to the tank truck’s top hatches at a bottom loadout terminal.

The tank truck load-out terminal is designed so that drivers can safely load their trucks without assistance from other personnel. Multiple trucks can be filled simultaneously. Truck operators access the top hatches on the tanks for venting and inspection. SafeRack’s access platform is equipped with our patented safety gangway and safety cages, providing workers with safe and easy access to the top of their tank trucks.

Marathon’s Dickinson North Dakota refinery has a crude oil capacity of 19,000 barrels per calendar day (bpcd). Primarily processes domestic crude oil from North Dakota and manufactures ultra-low sulfur diesel and gasoline blendstocks, which are distributed by truck and rail.

This refinery is planned to be converted into a 12,000 bpcd, 100 percent renewable diesel facility, which will process refined soy oil and other organically derived feedstocks.

Source: Marathonpetroleum.com

The #1 Selling Gangway in North America

In another industry first, RetractAlok technology Lift, Lower & Lock’s in any position automatically with no manual lifting

NEW PRODUCT OF THE YEAR!

NEW PRODUCT OF THE YEAR!

The Occupational Health & Safety New Product of the Year awarded to SafeRack’s GX Gangway in the Fall Protection/Prevention category.

- Powered Lift & lower system– Improved ergonomics for healthier employees and a safer workplace.

- Positive locking system in any position– Protects drivers and operators automatically.

- Plug and Play– Installed, pre-set, and calibrated for fast and easy installation.

- Consultative Approach– On-site visits to develop the system that’s right for you.

- Expedited Delivery– Quick ordering, in-stock parts, and fast delivery

- Precision Built– Proudly made in the USA. Fewer parts and less welds result in stronger, longer life, with less maintenance

- Custom Solutions– Many options and sizes available to suit any application.

Gangways and Loading Ramps for Railcar, Truck, and Marine

SafeRack designs, builds and installs safe, ergonomic, and efficient loading platform gangways for small and large facilities globally. Backed by years of experience and a hands-on, collaborative approach, the patented solutions are delivered on time, every time. And, just as important, they come within budget and without hassles.

Call for an on-site visit to make sure you get the railcar gangways, truck gangways, or marine gangways that fit and work as you expect. SafeRack representatives visit your site and help with complex retrofits or new greenfield applications.

(Self-Adjusting Stairs) | (Self-Adjusting Stairs) | (Flat Ramp Loading) | (Telescoping Flat Ramp) | |

| Vehicle(s) | Truck loading | Truck loading | Loading Hopper RailCars | Loading Liquid Tank RailCars |

| Attributes | Easily Adjusts to different vehicle heights | Easily Adjusts to different vehicle heights | Telescoping extension to adjust for Railcar crash boxes or applications that don’t require safety cage | |

| Width/ Range | 24″, 36″, 48″, 60″, 72″ 45° Up/40° Down | 24″, 36″, 48″, 60″, 72″ 45° Up/40° Down | 24″, 36″, 48″, 60″, 72″ 15° Up/15° Down | 24″, 36″, 48″, 60″, 72″ 15° Up/15° Down |

| Options | Safety Cage Power Options: Pneumatic, Corrosion Resistant Pneumatic, 110V (via 12 volt system), Solar (via 12 volt system), 208V (without 12 volt system) | Safety Cage | Safety Cage | |

| Load | 500lbs | 500lbs | ||

| Materials | Aluminum with stainless steel hardware | Aluminum with stainless steel hardware | Aluminum with stainless steel hardware. Stainless steel option | Aluminum with stainless steel hardware. Stainless steel option |

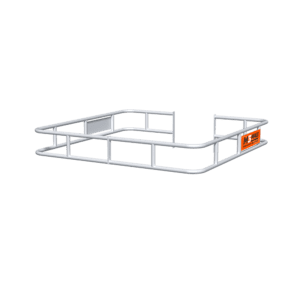

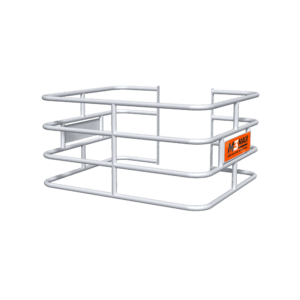

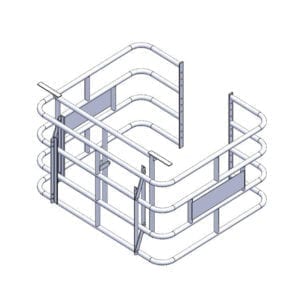

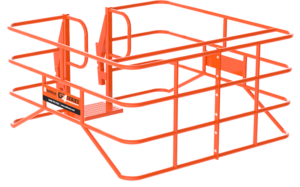

SafeRack Safety Cage Types

|  |  |  |  |

| 2-Rail Safety Cage | 4-Rail Safety Cage | ISOtainer Safety Cage | Offset Safety Cage | FracSand Cage |