SafeRack’s gangway with offset gangway for loading cement hopper truck

Built for the Cement Industry

Loading and unloading cement presents a unique set of challenges and risks. Typically, cement truck loading requires three stops, increasing the risk of human error threefold. To make matters worse, many workers, to account for trucks that are spotted incorrectly, attempt to lift the entire cage while atop those trucks. Company policies can only do so much to protect your workers and your business.

However, with the new G4 Series Offset Cage, your employees—and bottom line—are more protected than ever. The innovative cage, designed specifically for the cement industry, features a lockdown device that allows workers to lift the gangway only when safely on the platform and while pressing the footlock assembly.

Safety Is in the Details

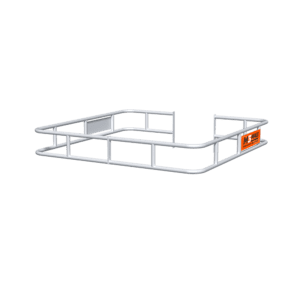

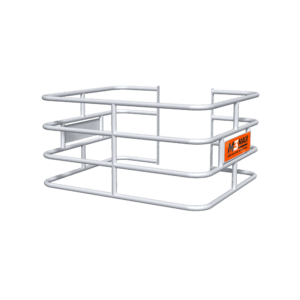

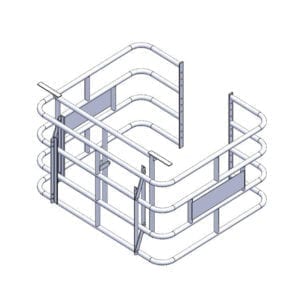

The G4 Series Offset Cage features flared and tapered rungs that give the lid a full range of motion while the equipment is in the working position. The design also ensures that the gangway and cage won’t have any interference when the equipment is lowered on top of the truck.

It’s designed to be used with both SFR and SAS gangways and can be offset to either the left or the right. And, like all SafeRack products, it’s built with safety and longevity in mind. The heavy-duty aluminum withstands whatever your job or Mother Nature can dish out. Plus, the three rails on both ends, along with four rails at the hatch area, provide a sturdy and secure workspace. Additionally, its large, 4’x7′ handrail footprint allows workers the room they need to stay productive.

Gangways and Loading Ramps for Railcar, Truck, and Marine

SafeRack designs, builds and installs safe, ergonomic, and efficient loading platform gangways for small and large facilities globally. Backed by years of experience and a hands-on, collaborative approach, the patented solutions are delivered on time, every time. And, just as important, they come within budget and without hassles.

Call for an on-site visit to make sure you get the railcar gangways, truck gangways, or marine gangways that fit and work as you expect. SafeRack representatives visit your site and help with complex retrofits or new greenfield applications.

(Self-Adjusting Stairs) | (Self-Adjusting Stairs) | (Flat Ramp Loading) | (Telescoping Flat Ramp) | |

| Vehicle(s) | Truck loading | Truck loading | Loading Hopper RailCars | Loading Liquid Tank RailCars |

| Attributes | Easily Adjusts to different vehicle heights | Easily Adjusts to different vehicle heights | Telescoping extension to adjust for Railcar crash boxes or applications that don’t require safety cage | |

| Width/ Range | 24″, 36″, 48″, 60″, 72″ 45° Up/40° Down | 24″, 36″, 48″, 60″, 72″ 45° Up/40° Down | 24″, 36″, 48″, 60″, 72″ 15° Up/15° Down | 24″, 36″, 48″, 60″, 72″ 15° Up/15° Down |

| Options | Safety Cage Power Options: Pneumatic, Corrosion Resistant Pneumatic, 110V (via 12 volt system), Solar (via 12 volt system), 208V (without 12 volt system) | Safety Cage | Safety Cage | |

| Load | 500lbs | 500lbs | ||

| Materials | Aluminum with stainless steel hardware | Aluminum with stainless steel hardware | Aluminum with stainless steel hardware. Stainless steel option | Aluminum with stainless steel hardware. Stainless steel option |

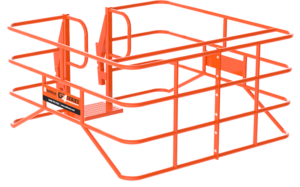

SafeRack Safety Cage Types

|  |  |  |  |

| 2-Rail Safety Cage | 4-Rail Safety Cage | ISOtainer Safety Cage | Offset Safety Cage | FracSand Cage |