Project Profile – Replaced 12 Marine Loading Arms on 3 docks

- Replace end-of-life marine loading arms with long lead times for replacement parts and expensive and time-consuming maintenance requirements.

- Enhance safety features beyond existing loading systems.

- Significantly reduce wind load on the docks.

- Improved flow rate – Achieve the same or better flow rate with reduced loading diameter without pressure drop.

- Eliminates the challenge of pushing products up 30-50 feet with traditional loading arms.

- Adapt to a hazardous environment (A Class 1, Division 2)

Installation and Operation

The installation of all 12 DockReels was completed successfully, marking it the first of its kind in the U.S. for marine loading. The new system is now fully operational, and its effectiveness has led the company to recognize it as a “Best Practice” in marine loading, instructing other locations to strongly consider replacing loading arms with DockReel loading systems.

| Location | Beaumont, TX |

| Industry | Chemical |

| Key Products | DockReel systems |

| Project Partners | SafeRack, Techflow Marine |

Challenges and Solutions

The project faced several challenges, including unexpected delays due to supply chain issues persisting from the Covid-19 pandemic, staffing changes, and complex logistics. However, the team, including personnel from SafeRack and Techflow Marine, demonstrated exceptional commitment and problem-solving skills, overcoming these hurdles effectively.

Customer Feedback

Direct quotes from key personnel at the chemical company highlight the successful collaboration and innovative nature of the project. Appreciation was expressed for the engagement and support from collaborating partners, with hopes for future collaborations.

Recognition was also made of the technology as a groundbreaking application in the industry, setting a precedent in the U.S. Praise was offered for the teamwork and partnership formed during the project’s execution.

Customer Quotes

Company and Customer name redacted per company policy

“We would not have been able to deliver this project flawlessly without the great engagement and support from TFM and SafeRack. I hope we ([customer name redacted for privacy], TFM and SafeRack) can work together in the future together, whether at Beaumont or at another site. Keep up the fantastic and innovative work!”

– Business Team Leader

“I will keep bragging on the innovative application of this technology – first in the downstream and chemical sectors of our company, and first in the USA. Awesome to be leading the world in this space. Thank you!”

– Business Team Leader

“It was great to meet in person and celebrate the first successful install of TFM hose reels in the U.S.! Looking forward to completing phase 2 of the install with the team and a long-term partnership with TFM/SafeRack.”

– Lead Project Engineer

“I really appreciate the way that we have all come together as one to execute this very important project with George and his team. We should be proud of the bonds and partnership formed here, and the incredible tenacity demonstrated to complete this installation. We look forward to future partnerships with SafeRack and TFM.”

– Site Project Manager

Onshore and Nearshore Loading Equipment

Marine Loading and Unloading Systems

A full range of products and services of Fluid Transfer Systems, Hose Handling Systems, Tandem Mooring Systems, Large Bore Flexible Hose Systems, Marine Coupling Systems, and Loading Platforms.

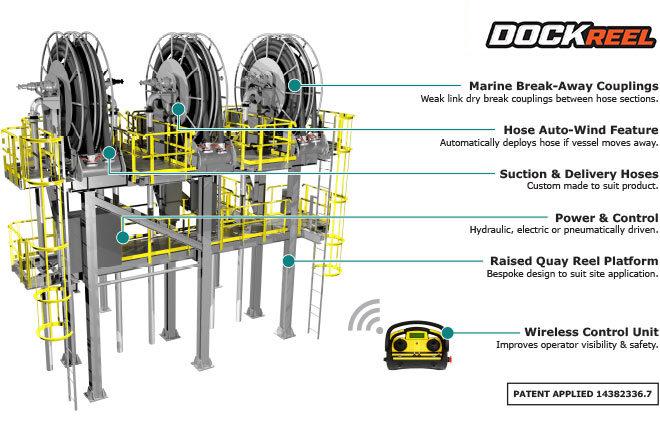

DockReel – A New and Efficient Marine Loading Arm Alternative

Gone are the days of inefficient, heavy, and maintenance-prone marine loading arms. Welcome to the new world where flexibility, lower operating expense, and advanced safety features are at your fingertips. Couple that with local support, available spare parts, and the world leaders in loading and unloading technologies, and you’ve got a solution that will serve you and your customers long into the future.

Results and Future Prospects

The successful installation has not only optimized the loading process but also set a high standard for future marine loading endeavors. The company is now planning to expand its use of DockReel systems, with an immediate order for additional units. One unexpected benefit found was that the system is so quiet that the operators had to confirm with the control team that product was flowing, and they were able to reduce the valve positions from 25% to 8% while still retaining the same flow rate, proving the superior flow characteristics of the DockReel over traditional Marine Loading Arm systems.

Conclusion

This pioneering project in Beaumont, TX, has demonstrated the feasibility and advantages of the DockReel system in a challenging industrial environment. It stands as a testament to innovative technology and effective collaboration, paving the way for future advancements in marine loading solutions. Surpassing the safety features of traditional loading technologies and providing superior benefits of dock load reductions, smaller dock footprint, reduced infrastructure requirements,