The Evolution of the Gas Pump

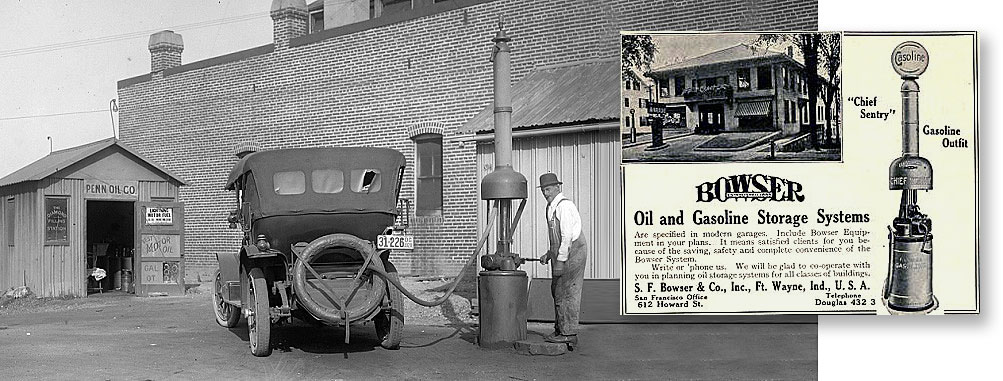

Before motoring, hardware stores and general stores would store kerosene in large tanks to be ladled into customer containers. It was 1885 in Fort Wayne, Indiana where kerosene gas pump inventor, S.F. Bowser sold his first, newly invented kerosene pump to the owner of a grocery shop. This was to solve the problem and mess of a storekeeper ladling flammable liquid into whatever random container the customer brought. At that time, kerosene would fuel stoves and lamps. Gasoline was just a volatile byproduct of refining kerosene.

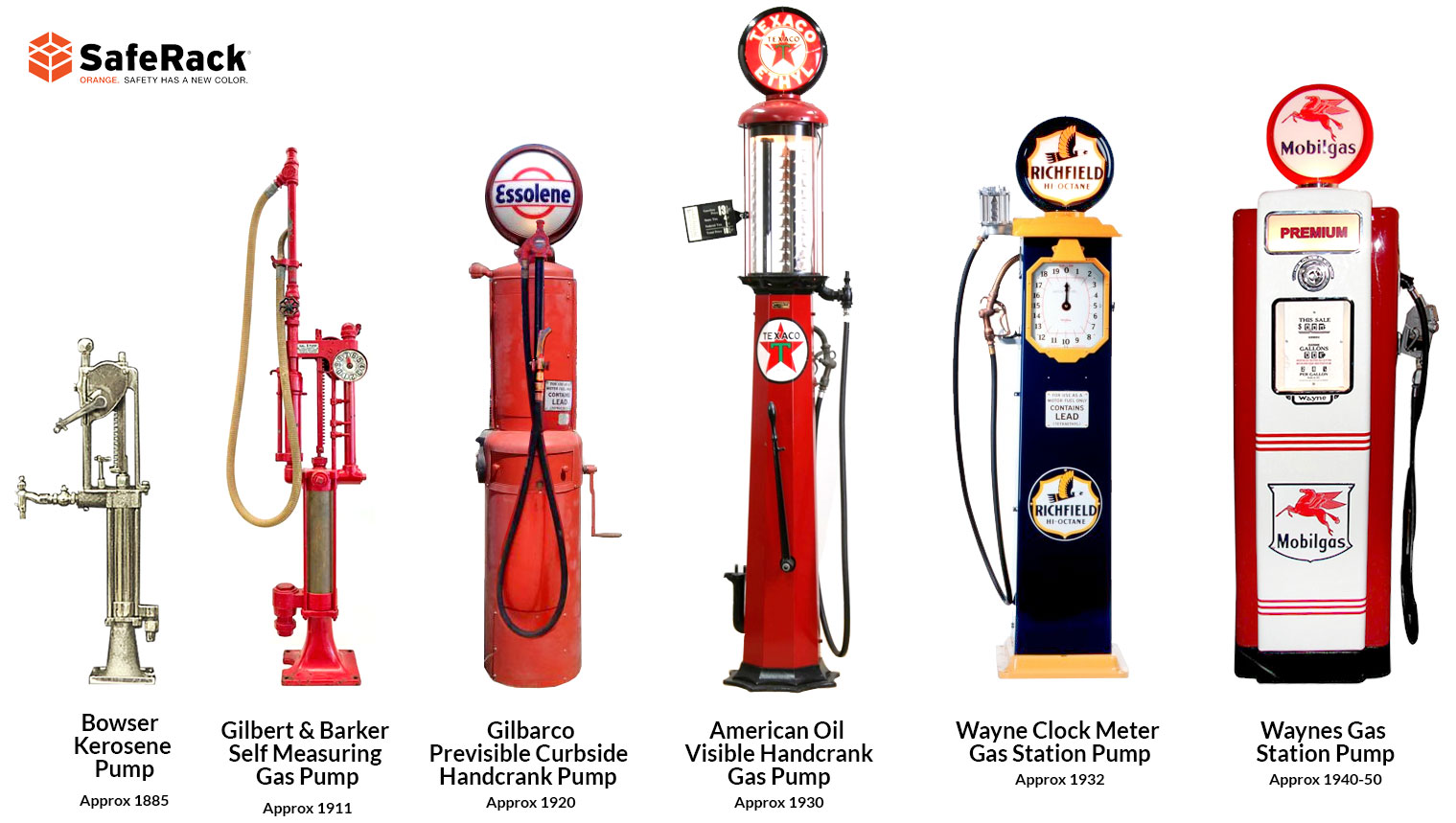

Bowser’s invention, which reliably measured and dispensed kerosene – a product in high demand for nearly 50 years – soon evolved into the metered gasoline pump. The original Bowser pump was utilitarian looking, made up of a square metal tank with a wooden cabinet equipped with a suction pump operated by a manual hand-stroke lever. In 1905, a hose attachment was added for putting gasoline directly into the fuel tank.

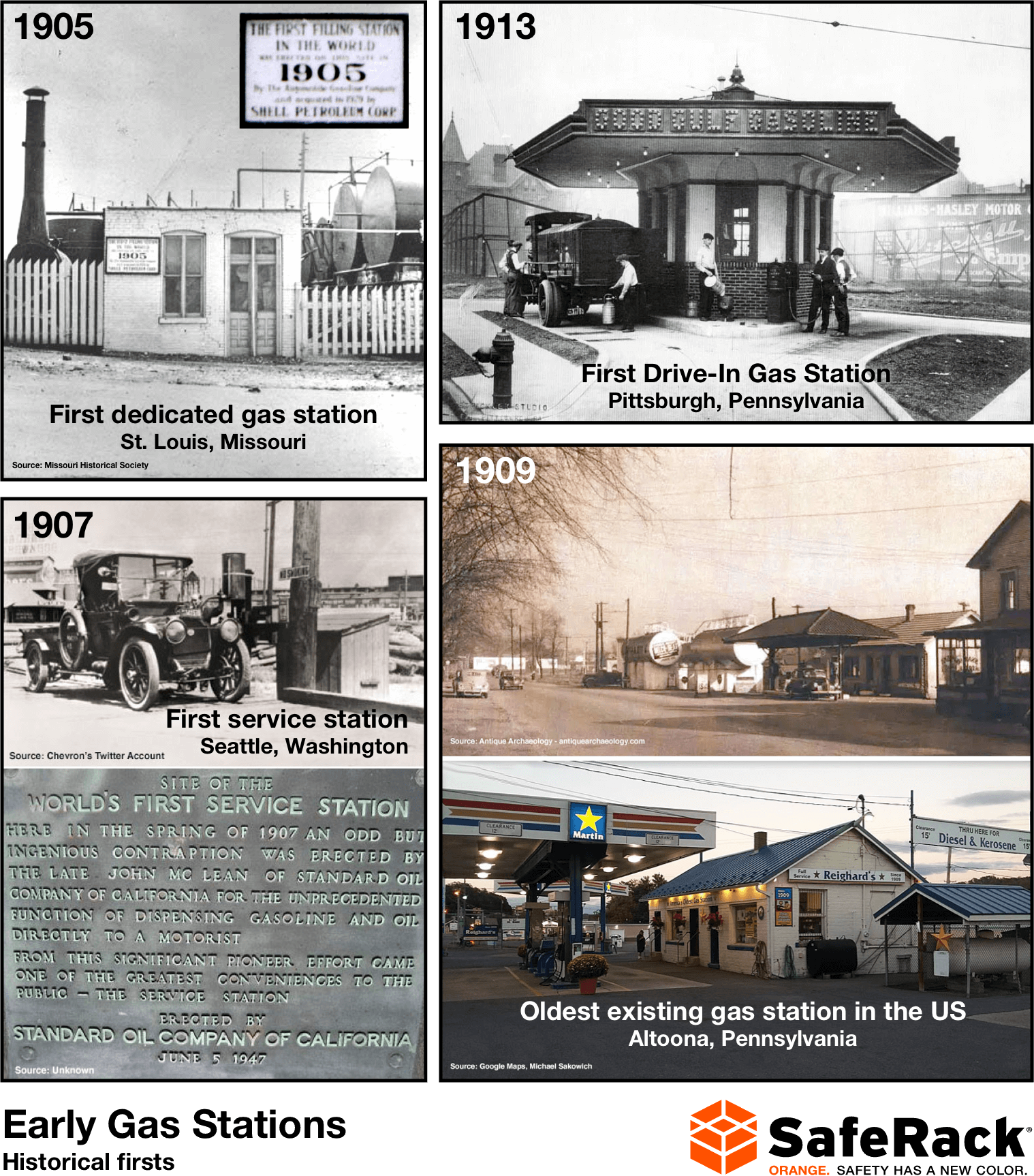

In around 1910, automobiles were becoming commercially available. With already established relationships with refineries, hardware stores, general stores, and even pharmacies would sell the gasoline needed for combustion engines. Gasoline, a highly flammable liquid, was stored in large above-ground tanks or curbside in 5-gallon tanks. Located in city centers, this large quantity of flammable liquid stored in general and hardware stores would present serious fire risks. After a series of fires and explosions, regulations forced businesses selling gasoline to be moved from city centers to the roadways beyond the cities.

There are a few claims for the first-ever drive-in gas station. Standard Oil claims it had a station in Seattle, Washington in 1907, while it’s also been argued that the first appeared in St. Louis a few years earlier. However, most recognize that when “Good Gulf Gasoline” went on sale in downtown Pittsburgh in 1913, the first true drive-in service was opened. “On its first day, the station sold 30 gallons of gasoline at 27 cents per gallon. On its first Saturday, Gulf’s new service station pumped 350 gallons of gasoline,” noted the Pennsylvania Historical and Museum Commission. The station was located directly next to car dealerships, leading new car owners to fill up directly after pulling off the lot.

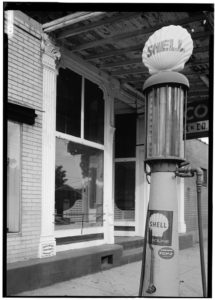

This was really the start to manufacturers enclosing the mechanics of the curbside pumps in cabinets. These cabinets ranged in design and style. Some basic cabinets simply stored the parts of the machinery, whereas others were more stylized. These were the early days when company logos started to appear on the pump, either directly on the cabinet or on a globe above the pump.

Image source: Library of Congress

Gas Pump Timeline:

1890 to 1900 – hand pump with no measurement device

1900 to 1910 – hand pump, some with clockface for measurement

1910 to 1920 – hand pumps with minimal color. Some with clockface (possibly attached visible attachment)

1920 to 1930 – hand pumps, some with color, some with clockface, some with glowing marketing globe on top

1930 to 1940 – art deco style with color, some with both clockface and glass cylinders, glowing globe on top

1940 to 1950 – square styling and color, electronic with clock face and cylinder, some with sight glass (smaller cylinder), still has a glowing globe on top

1950 to 1960 – box style only, glowing computerized measurement and price calculation

By 1918, the first visible pump was introduced. The customer was able to see just how much fuel he was purchased by the inclusion of a large glass cylinder that was hooked up to the pump. When first introduced, the glass cylinders were retrofitted to curbside pumps that already existed. In 1923 companies started to develop new pumps with the cylinders attached directly to them. This was also the early foray into experimenting with motorized pumping mechanisms versus the manual hand crank. Around 1925, the visible cylinder was replaced by the clock-style meter, which was a dominant feature of early 1930s gas pumps.

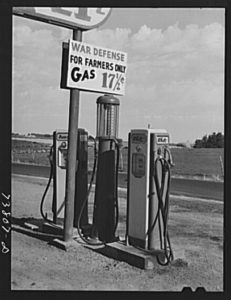

1934 was the year that the computer meter was developed by the Wayne Pump Company. With this invention was the departure from the traditional clock-face style replaced instead by a more digital form. Gallons and prices were displayed directly on the face and this caught on quickly. By the late 30’s, all companies used the computer meter. This was the beginning of the Art Deco period as well, which embraces the machine aesthetic. Gas pumps in this era were geometric in shape and featured stepped and vibrant patterns with stainless steel. Although the edges were slightly rounded, the overall pump was squarer in its look. This style was dominant throughout the WWII years, as the government limited their manufacturing.

Once the Second World War ended, cars got lower and therefore it became an obstacle trying to view meters from the car’s new lower perspective. As a result, new, shorter gasoline pumps were designed, which were called low-profile pumps. For the most part, these pumps featured rounded edges, stainless steel trim, large meter faces, and simpler details than what was seen in the Art Deco designs of the 1930s.

Continuing into the 1950’s the trend continued to move away from rounder edges and the stainless steel pump was popular. The hardware was shorter, squarer in shape, and featured unpainted, stainless steel surfaces. The top part of the pump was often larger, setting atop a narrower, tapering base. The units were often set up adjacent to one another in long rows, providing different types of fuels and services.

“Today, 152,995 gas stations dot the landscape, including 123,289 convenience stores,” Ernst reports. On average, each location sells about 4,000 gallons of fuel per day, “quite a jump from the 30 gallons sold at the Gulf station in Pittsburgh on December 1, 1913.”

Early Gas Stations

In the early years of motoring, before dedicated gasoline stations existed, motorists would buy gasoline from hardware stores, general stores, pharmacies, and even blacksmiths. These businesses had pre-existing relationships with the refineries through their sale of kerosene which was used as a lighting fuel. Stored in five-gallon cans stacked curbside or in large above-ground tanks, the fuel was poured into the automobile’s gas tank using a funnel with a chamois as a filter.

Due to the fire dangers and a series of incidents, public concern and regulators would force the sale of gasoline to dedicated retail facilities outside of city centers.

Several locations around the country claim to be the site of the nation’s first gasoline station, known to motorists at the time as “filling stations. Learn more about the first gas stations

Gas is flowing throughout the country in mass quantities every day. Whether it’s filling your car tank or being transported, having the proper and safe machinery to handle this liquid is key. In the early 1900’s, a hose was included to the pump to allow for direct pumping. Nowadays hoses include swivel joints and safety breakaways to ensure safe transportation and transfer of liquids.

The Modern Gas Pump is laden with new features but the mission is still the same. The pump has to efficiently transfer and account for fuel that is stored in an underground tank to the consumer’s fuel tank. The use of swivel joints is standard to allow for easy placement of the fuel nozzle to the vehicle’s fuel tank. Vapor recovery systems are also standard and in some cases required on today’s pumps. These systems return escaping vapors back to the tank to accomplish two things…

- Protect the environment

- Stop product loss

Other items on modern pumps include more accurate accounting to the seller and consumer by using modern flow metering. Today’s pumps often have small video screens that relay news items, and advertisements. Point Of Purchase card readers allow for at the pump payment and for loyalty program tracking which passes on savings and product deals to consumers.

SafeRack is the leading distributor of liquid transfer systems, so whether it’s swivel joints, loading arms, or liquid transfer coupler or adapters, our knowledgeable experts create a system customized to any liquid transfer environment.

Sources/References: